Take Complete Control of Your Discrete Manufacturing Processes

Easier Way to Efficiently Manage Your Business

Lot/Serial Traceability

Drill down into the inventory detail to quickly recall products, match replacement parts, track production and check faulty components in an item

Project Management

Manage successful and profitable projects through their entire lifecycle with robust, integrated project management capabilities

Shop Floor Control

Prioritize, track, and manage all aspects of your production leading to improved planning, scheduling, and costing

Quality Control

Tools and workflow capabilities needed to maintain and retain the highest quality standard, including proactive monitoring through complete product traceability

BOM Planning

Delivers robust single and multi-level bill of materials (BOM) management to ensure the highest levels of product consistency, quality, and collaboration

Estimating

Create a custom quote, copy and modify from new and existing BOM. Compare quotes from previous work orders. Create new parts on the fly, revise quotes. Compare actual cost vs. estimates.

Enterprise Resource Planning and accounting software designed for small and medium-sized businesses in manufacturing, distribution, finance, services, retail, non-profit, and many other industries, with this you get:

- Powerful functionality

- Greater flexibility

- Real time insights into your organization

Sage 300cloud connects your entire business, including customer relationship management, inventory management, human resources, and accounting, with an integrated solution.

Built for growth-focused businesses that want to lead through operational excellence. Unite data access across departments including inventory, human resources, accounting, finance, manufacturing, and distribution and makes data readily available across departments

- Insight into customer relationships to help you expand existing and new sales channels

- Functional support to expand your business across locations, languages and currencies

- Simple and flexible software that gives employees the tools to improve their productivity

Sage X3 uses visually-driven workflows in an intuitive interface that’s easy for anyone to quickly understand and interpret

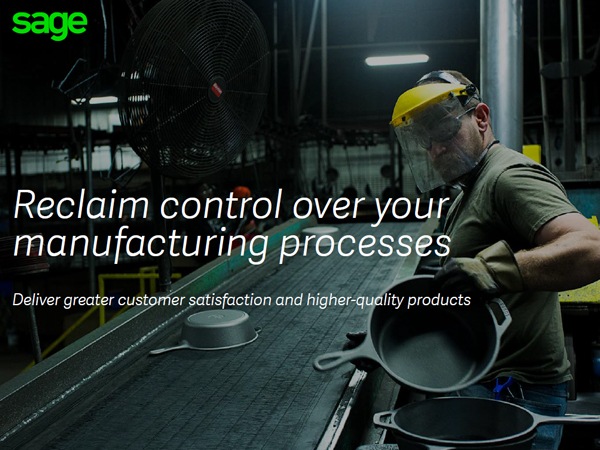

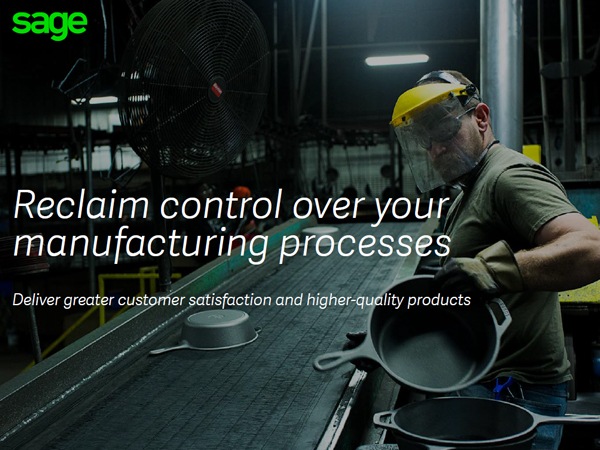

Reclaim control over your manufacturing processes with our following solutions

Create customer quotes on the fly with Sage X3 Quote Estimator By IWI Consulting Group

Achieve Greater Business Insight and Visibility

Modern discrete business solution can help organizations gain total visibility and complete control of all aspects of your manufacturing process.

Improved Inventory Management

Visibility into your supply chain and stock levels improves industry turns to help reduce total overhead and costs

Increased Customer Satisfaction

Reduce unexpected delays and improve overall product quality with real-time control and monitoring, in turn boosting overall customer satisfaction.

Streamlined Schedule Compliance

If drafted production scheduled don’t meet expectations, the results for your ROI can be devastating. Control over all aspects of your production process help increase schedule consistency and compliance

Enhanced Data Analysis

With Cloud solution makes it possible to combine, harmonize and mine heterogeneous data sources to enable in-depth analysis and faster decision making

Reduced Process Complexity

Complex processes are prone to failure. Modern cloud discrete manufacturing solution offers process management by exception - rather than by the rule - to reduce complexity and increase reliability

Deliver greater customer satisfaction and higher-quality products

Learn how you can take full control of your discrete manufacturing process using business solution

Go Live in 39 Man Days with a pre-configured system at less cost or take your business to the next level with our Standard implementation

Rapid Implementation

Get your business management solution up to speed with IWI Consulting’s Rapid Implementation.- Enhanced control

- Improved workflows

- Increased productivity

- Reduced support requirements

Sage Full Implementation

Take your business to the next level with full Sage implementation.- Lack of interoperability between multiple systems

- Operational needs that exceed current capabilities

- Over-reliance on legacy solutions such as Excel

- Abundance of time-consuming manual processes

Minimize your manual processes by integrating your disparate systems to gain the most from your software investment, get a complete integrated ERP system. We provide custom integrations:

eCommerce Integration

Real Time Exchange Rates

Automatic update of any currency exchange rates update from different sources like Bank of Canada and XE.

Shipping App Integration

Warehouse Optimization

Production Floor Integration